Activated Carbon

Granular & Powdered Forms- High internal surface area

- Rapid diffusion kinetics

- Greater loading capacity

- Customisable particle sizing

- Manufactured by an ISO9001 accredited Quality system

Quality coal and carbon products

James Cumming & Sons is an industry leader in environmentally friendly water and wastewater filtration.

Internationally recognised, our premium Australian Filter Coal and Activated Carbon products effectively address health risks linked to water and soil contamination.

We manufacture to exact specifications and service various industries, including potable water, wastewater, process water, desalination pre-treatment, construction, glass manufacturing, soil remediation, iron foundries, civil engineering, steelworks industries.

Our commitment to compliance and innovation ensures our products meet stringent environmental standards. By continually refining our mineral processing standards, we help industries improve efficiency and sustainability.

Water intended for human consumption must meet the Australian Drinking Water Guidelines 2004 or equivalent. These guidelines are in place to ensure the safety and quality of drinking water.

We manufacture and supply C&S Brand Australian Filter Coal and Support Media for the potable water industry, servicing water filtration plants across Australia, South East Asia and the Middle East.

Additionally, we supply a range of Powdered and Granular Activated Carbons for enhanced water quality and the removal of algal taste, odours and colours, as well as MIB (methyl-isoborneol) Geosmin, microcystin & saxitoxin.

Potable water treatment facilities rely on our products for their superior ability to remove harmful organic compounds. Our solutions help ensure safe, clean water that meets regulatory standards.

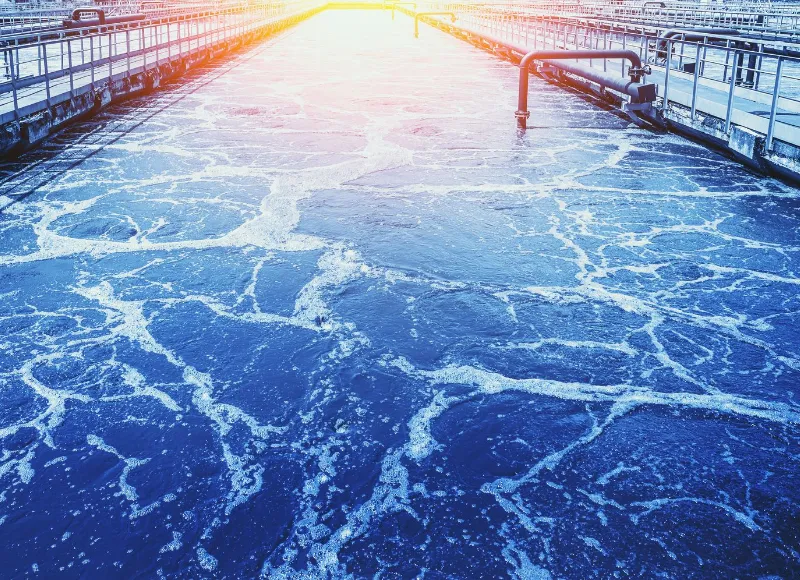

The wastewater industry plays a pivotal role in environmental stewardship by responsibly disposing of water utilised in industrial and commercial processes.

James Cumming & Sons supplies C&S Brand Australian Filtration Media and Support Media to resource recovery plants to assist in treating wastewater to tertiary standards to meet water authority requirements.

We customise our premium products to meet client specifications, delivering high-performance solutions. Our wastewater filtration solutions are tailored to optimise resource recovery and environmental compliance. Enhancing wastewater treatment processes helps industries reduce their environmental impact and promote sustainable water use.

Process water is essential for diverse industries such as paper and pulp mills, steel mills, sugar refineries, mining sites and large industrial and agricultural operations.

In process water filtration, precision and efficiency are crucial. James Cumming & Sons supplies high-quality Filter Media, essential for treating water in manufacturing processes and ensuring compliance with discharge standards.

We tailor our products to specific purposes and industries, manufacturing them to project specifications.

Desalination is the process of extracting salt from seawater. It offers a sustainable water solution that is critical in addressing worldwide water scarcity.

James Cumming & Sons manufactures and supplies dual-media filtration media for reverse osmosis (RO) pre-treatment to ensure the longevity of RO membranes, also optimising the process in subsequent stages.

We manufacture our dual-media filtration products to exact specifications and supply them in a timely and safe manner.

Water filtration is vital for the construction industry and in contributing to sustainable and eco-friendly building practices.

James Cumming & Sons supplies Filter Media to project management and construction organisations requiring these products for their larger scale projects. These solutions are key in mitigating runoff pollution and enhancing water conservation efforts on-site.

We collaborate with our construction industry clients to deliver tailored filtration solutions that contribute to seamless project execution and the efficient management of natural resources.

The glass manufacturing industry heavily relies on specialised carbon products for the colourisation process to achieve vibrant and consistent colours.

James Cumming & Sons supplies premium colourisation carbons for glass bottling plants all around Australia and South East Asia that exceed the stringent quality and consistency standards.

Our industrial-graded coal is a cost-effective solution, and we are able to collaborate with fellow manufacturers to tailor mineral processing products for specific application needs.

By refining our carbon products for precise colourisation, we enable our clients in the glass manufacturing sector to maintain high production standards while reducing waste and energy use.

Soil remediation relies on specialised activated carbon products to address soil contamination issues by removing, neutralising or stabilising pollutants and hazardous substances.

At James Cumming & Sons, we manufacture and supply premium Activated Carbons and coal-based products for the adsorption and retention of hydrocarbons, PAHs (polycyclic aromatic hydrocarbons), PFAS (per- and polyfluoroalkyl substances) and PFOAs (perfluorooctanoic acid).

Our commitment extends to safe packaging and delivering our specific solutions for the soil remediation industry with care. These solutions not only restore contaminated sites but also promote long-term environmental health by preventing further pollutant spread.

Iron foundries depend on a range of essential materials, including coal, blackings, graphites, metallurgical cokes, terra flakes and bentonite blends, to drive iron manufacturing and the efficiency of casting processes. Milling, packaging and servicing the iron foundry industry is a core part of our 115-year heritage.

At James Cumming & Sons, we have an extensive understanding of the iron foundry industry’s requirements, and we are committed to delivering ongoing support and premium products. Our in-depth industry knowledge allows us to continuously innovate and provide foundries with the materials needed to optimise production and improve casting precision.

The civil engineering industry relies on coal and carbon products for key applications in large infrastructure projects, from producing high-strength concrete and steel to powering industrial furnaces.

James Cumming & Sons reliably supplies premium coal and carbon for use in civil engineering. This ensures long-lasting infrastructure that can withstand heavy use and harsh environmental conditions.

Our clients can trust that our products consistently meet the rigorous standards necessary for civil engineering projects, assuring the quality of their work. By supplying essential materials for critical infrastructure, we help professionals achieve long-lasting results across various applications.

Vital steelworks processes depend on Filter Media for wastewater, as well as coal, carbon and coke products, serving as fuel for furnaces and essential reducing agents in blast furnaces.

James Cumming & Sons has supplied the steelworks industry with these critical materials for over a hundred years. We are a trusted partner in the steelworks sector, contributing to the efficiency of steel production and the quality of final products by providing premium products.

Our coal and carbon materials expertise helps optimise blast furnace performance, reducing energy consumption and enhancing steelwork production.

The thermal industry across Southeast Asia relies on coal and carbon products for vital applications such as power generation and boiler operations.

James Cumming & Sons manufactures and supplies coal for the thermal industry. Our advanced crushing processes guarantee products that are fit for industry purposes.

We ensure that our materials not only meet the stringent requirements of power generation but also contribute to the reliability and sustainability of the thermal sector.

By delivering high-grade coal, we support efficient energy generation while helping to reduce emissions and promoting cleaner thermal power solutions. Our commitment to quality control ensures consistent sizing and performance of our coal, maximising combustion efficiency and reducing emissions.

At James Cumming & Sons, we control every stage of the process, from sourcing the highest-grade Australian coal to delivering the final product. This end-to-end approach ensures uncompromising quality and allows us to tailor our offerings to meet the needs of each industry we serve. Our products are carefully processed, packaged for reliable transport and delivered with a focus on safety and environmental responsibility.

We source the highest-grade Australian coal from a trusted network of suppliers, ensuring a consistent and premium product.

Advanced crushing technology ensures precise particle size distribution for various applications.

Specialised screening equipment ensures compliance with exact sizing requirements, reducing by-products.

On-time delivery with robust packaging ensures safe transport across Australia and international destinations.

For over 115 years, James Cumming & Sons has been a trusted partner to Australian industries. Our legacy is built on sourcing the finest Australian coal and rigorously processing it to meet the precise requirements of our clients across industries — from water treatment plants to foundries, steelworks and beyond.

Our experts are ready to collaborate with you and provide custom solutions that optimise your operations and contribute to your success. Contact us today to discuss your industry-specific requirements.

for your Filter Coal, Activated Carbon and Carbon additives

James Cumming

319 Parramatta Road,

Auburn NSW 2144 Australia

© Copyright 2025 James Cummings & Sons Pty Ltd. Website by Brilliant Digital

The C&S Brand™ logo are trademarks of James Cumming & Sons Pty Ltd.

ABN 98 000 453 378